| Issue |

EPJ Appl. Metamat.

Volume 11, 2024

|

|

|---|---|---|

| Article Number | 4 | |

| Number of page(s) | 7 | |

| DOI | https://doi.org/10.1051/epjam/2024005 | |

| Published online | 01 March 2024 | |

https://doi.org/10.1051/epjam/2024005

Research article

Using RAM method for optimal selection of flame retardant nanocomposite material fabrication solution

School of Mechanical and Automotive Engineering, Hanoi University of Industry, Hanoi, Vietnam

* e-mail: doductrung@haui.edu.vn

Received:

24

October

2023

Accepted:

6

January

2024

Published online: 1 March 2024

This study aimed to optimize the selection of manufacturing solutions for flame retardant nanocomposite materials based on polyvinyl chloride (PVC). A total of eight different options were considered. The first option utilized PVC as the base material, and the subsequent options were carried out by adding specific amounts of reinforcing agents, including aluminum hydroxide (ATH) and zinc borate (ZB). The seven following options were denoted by their respective symbols: 5ATH/PVC, 10ATH/PVC, 15ATH/PVC, 5ZB/PVC, 10ZB/PVC, 15ZB/PVC, and 5ATH/5ZB/PVC. The number preceding the symbol of the reinforcing agent represents the percentage of the reinforcing agent added to the PVC material. For example, 5ATH/PVC signifies the addition of 5% of ATH reinforcing agent to the PVC material. To evaluate each option, five different indices were employed. The weight for each index was determined using four different methods, including the Equal method, Entropy method, MEREC method, and LOPCOW method. The RAM method was used to select the best option. The combination of the RAM method and the four weight determination methods generated four different datasets of option rankings. In all four of these datasets, the best and worst options consistently matched. The results indicated that the 15ATH/PVC option was deemed the best, while the pure PVC option was the worst.

Key words: Flame retardant nanocomposite material / ATH / ZB / MCDM / RAM method

© D.D. Trung, Published by EDP Sciences, 2024

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

In the context of modern material research, the study of metamaterials has played a crucial role in developing and enhancing the physical properties of fundamental materials. Metamaterials are structures designed to exhibit specific physical properties that are often not naturally present [1]. Research on metamaterials focuses on optimizing properties such as elasticity, conductivity, sound insulation, and thermal conductivity, among many other attributes, opening up diverse applications across various fields [2]. Polyvinyl chloride (PVC) is a type of metamaterial that plays a significant role in numerous industries due to its distinctive properties. With its high chlorine content, PVC exhibits excellent flame resistance. In the construction industry, PVC is widely used in the production of water pipes, gas conduits, and insulation materials. Its flame resistance capability helps reduce the risk of fire propagation [3]. In medical applications, PVC is used for blood conduits and other medical products, ensuring safety during use [4]. In the electronics industry, PVC serves as an insulating material for cables and electronic wires, and its flame-resistant properties guarantee the safety of electronic devices [5]. In the automotive sector, PVC is used for interior lining and car insulation, providing fire protection in case of accidents [6], and so on. However, to enhance its processability, plasticizers are often added, which may diminish PVC's flame resistance. On the other hand, the addition of plasticizers can limit its thermal stability and resistance to oxidation [7]. To overcome these limitations, the method of creating nanocomposite materials has been employed. Nanocomposites consist of a PVC matrix and nano-sized inorganic flame-retardant materials. This material combines the advantages of organic polymers and inorganic materials [8]. Two common inorganic flame retardants used for supplementation in PVC are aluminum hydroxide (ATH) and zinc borate (ZB). These are cost-effective, non-toxic, and have good compatibility with polymer matrices. Recent research on flame-retardant PVC materials has shown that the presence of ATH or ZB during combustion restricts the generation of corrosive, harmful gases, reduces smoke emissions, and enhances flame resistance [9,10]. When using flame-retardant PVC materials, various parameters need to be considered, such as heat resistance, flame resistance, ignition time, heat transfer ability, waterproofing, corrosion resistance, sound insulation, tensile strength, elongation at break, elastic modulus, and limiting oxygen index to maintain flame [11]. However, different proportions of ATH and ZB can alter the mechanical properties of the compound [12–14]. Numerous studies have indicated that varying the content of ATH or ZB affects the compound's properties [15–18]. For a specific content of ATH (and/or ZB), the properties of the compound are not the same, and in some cases, they may even be contradictory [19–23]. This suggests the need to determine the content of ATH (and/or ZB) added to PVC material to achieve the desired values. Multiple Criteria Decision Making (MCDM) is a well-known technique for solving problems with conflicting criteria (parameters) [24–27]. The use of MCDM techniques allows for the determination of the best solution among available options. Over 200 different methods can be applied in MCDM [28]. The RAM method is the latest MCDM method [29]. RAM has the advantage of compensating for the trade-off between favorable and unfavorable criteria. It also overcomes the phenomenon of rank reversal [29]. It is important to emphasize that rank reversal is a phenomenon where the ranking of options changes when the weights of criteria are altered or when the method of normalizing data is modified. For instance, when adjusting the method of determining weights for criteria or changing the method of data normalization, an option initially identified as the best may cease to be the optimal choice; in some cases, it might even become the least favorable alternative. This is a complex phenomenon in the multi-criteria decision-making process. However, since it emerged in September 2023, the advantages of RAM method have not been explored in any existing literature. This is the reason it is being applied in this study. The procedural summary of applying the RAM method will be presented in the second part of this paper. When using RAM specifically, as well as MCDM methods in general, the rankings of the alternatives can change as the weights of the criteria change. For this reason, four different methods have been employed to calculate the criteria weights. The objective of this endeavor is to provide a solid conclusion on the absolute best solution for manufacturing flame retardant materials. A summary of the utilization of criteria weight determination methods is outlined in Section 3. In Section 4 of this article, the selection of the optimal solution for manufacturing flame retardant materials will be elaborated upon using the employed methods (RAM method and criteria weight determination methods). The final part of this research comprises the achieved results and the future work to be carried out.

2 The RAM method

The steps for using the RAM method to rank alternatives are as follows [29].

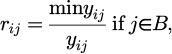

Step 1: Construct a decision matrix with m rows and n columns, where m and n correspond to the number of alternatives to be ranked and the number of criteria for each alternative, respectively. Let xij represent the value of criterion j for alternative i, where j = 1 ÷ n and i = 1 ÷ m. The letters B and C are used to denote the respective criteria for benefit and cost.

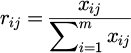

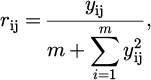

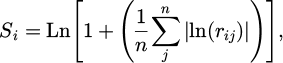

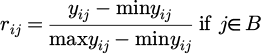

Step 2: Normalize the data using formula (1).

Step 3: Calculate the normalized values, considering the weights of the criteria, according to (2).

where wj is the weight of the jth criterion.

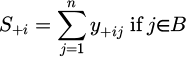

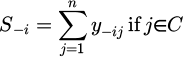

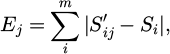

Step 4: Calculate the total normalized score, taking into account the criteria weights using (3) and (4).

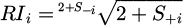

Step 5: Calculate the score for each alternative according to (5).

Step 6: Rank the alternatives in descending order based on their scores.

3 Criteria weight determination methods

Four criteria weight determination methods have been employed, including the Equal method, the Entropy method, the MEREC method, and the LOPCOW method. The Equal method is the simplest [30], while Entropy and MEREC are two recommended methods [31], and LOPCOW is considered the most recent approach [32].

When using the Equal weight method, all criteria have equal values [30].

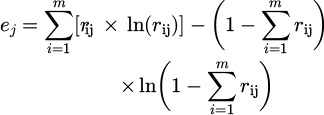

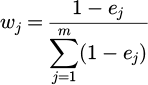

To calculate criteria weights using the Entropy method, you need to apply the formulas sequentially from (6) to (8) [31].

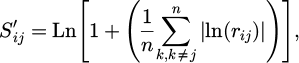

Applying the formulas sequentially from (9) to (14) to calculate criteria weights using the MEREC method [31].

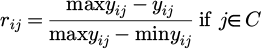

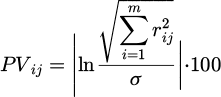

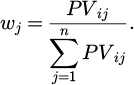

To calculate criteria weights using the LOPCOW method, you need to apply the formulas sequentially from (15) to (17) [32]. In (16), σ represents the standard deviation.

4 Selecting the optimal solution for flame retardant nanocomposite material fabrication

The selection of the best solution for manufacturing flame retardant materials is based on the results of a previous experimental study [33]. Seven solutions for manufacturing flame retardant materials by adding reinforcing agents have been implemented. Varying the percentage or type of reinforcing agent added to the original PVC material has created different solutions. To illustrate this, for instance, material “5ATH/PVC” means that 5% ATH was added to PVC. Another example is “10ZB/PVC,” which signifies the addition of 10% ZB to the PVC material. Table 1 displays information on eight types of flame retardant materials, with the first type being the original PVC material and the other seven being PVC materials with added reinforcing agents.

The pricing for each solution is determined using five parameters, which include tensile strength (C1), elongation at break (C2), elastic modulus (C3), total burning time (C4), and the limiting oxygen index to sustain combustion (C5). The physical properties (C1, C2, and C3) were measured according to ASTM D638 standards. Larger values of all three parameters are considered better (Type B criteria). Fire resistance (C4) was assessed according to ASTM D 3801 standards, and smaller values are preferable (Type C criteria). The limiting oxygen index (C5) is the minimum volume percentage of oxygen required to sustain the combustion of the material. This parameter is determined according to ASTM D 2863-97 standards, and larger values are better, indicating Type B criteria. All values of these parameters for various types of nanocomposite fire-resistant materials have been summarized in Table 1 [33].

Observing Table 1, we can see that the PVC base material has the highest values for both C1 and C2 among the eight options. In contrast, C3 and C5 have the highest values for the 15ATH/PVC material, and C4 has the smallest value, also belonging to this material type. This implies that there is no single material where all five parameters are the best. Determining a material choice requires considering the trade-off between all these parameters. This is an act of multi-criteria decision making (MCDM). To perform MCDM actions, the first step is to determine the weights for the five criteria (C1 to C5).

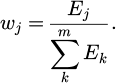

Formulas in Section 3 have been applied to calculate the weights for the criteria using four different methods, and the results have been consolidated in Table 2. We can observe that when using different methods, the weights of the criteria change significantly. The last row of this table demonstrates the percentage change in the weights of each criterion between the minimum and maximum values.

The application of the RAM method to determine the best solution is carried out in the following sequence. Normalized values have been calculated as per (1) and are summarized in Table 3.

The normalized values, taking into account the weights of the criteria, have been calculated as per (2). First, the set of criteria weights was computed using the Equal method. The computed results have been consolidated in Table 4.

The quantities S+i, S−i , RIi have been calculated using the respective formulas (3)–(5). The results after calculation have been consolidated in Table 5. This table also lists the rankings of the options based on the values of RIi.

Thus, the ranking of options when the criteria weights are calculated using the Equal method has concluded. The ranking of options when the criteria weights are calculated using the remaining three methods (entropy, MEREC, LOPCOW) has also been conducted similarly. In Figure 1, the chart illustrates the rankings of various options when the weights of the criteria are determined using different methods.

According to the data in Figure 1, in all four different scenarios (corresponding to four different methods for determining weights), the 15ATH/PVC material consistently emerges as the best material, while PVC is consistently identified as the worst material. It's worth noting that the weights of the criteria vary significantly when calculated using different methods (refer to the last row of Tab. 2). However, this factor does not alter the determination of the best solution. This provides strong evidence that 15ATH/PVC is the best material among the eight surveyed. In other words, adding 15% ATH to the base PVC is the best solution for producing fire-resistant materials. Looking back at Table 1, we observe that the tensile strength (C1) and elongation at break (C2) of 15ATH/PVC are both inferior to the base PVC material. However, the reduction in these parameters for 15ATH/PVC compared to the base PVC is negligible, at 8.56% for C1 and 5.32% for C2. In contrast, two modulus parameters, elastic modulus (C3) and the limiting oxygen index for flame maintenance (C5) of 15ATH/PVC, are better than those of the base PVC. C3 of 15ATH/PVC has increased by 11.63% compared to the base PVC, while C5 of 15ATH/PVC has increased by 25.49% compared to the base PVC. Particularly noteworthy is the flame resistance (C4) of 15ATH/PVC, which at 0.5 (s), is only 1/15th of that of the base PVC. This indicates that 15ATH/PVC excels in quality compared to the base PVC.

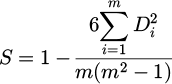

To conclude the process of using MCDM methods to rank the options, sensitivity analysis should be performed [34, 35]. The Spearman rank correlation coefficient has also been utilized for sensitivity analysis [34, 35], and it is calculated using formula (18). In this formula, Di represents the rank differences of options in a specific scenario compared to another scenario.

Table 6 summarizes the Spearman rank correlation coefficient values when comparing scenarios with each other.

The smallest value of the Spearman rank correlation coefficient in Table 6 is 0.8333, indicating that the rankings of options change very little in different situations [36]. It's also essential to emphasize that when using different methods to determine the weights for the criteria, the weight values of the criteria vary significantly (refer to the last row of Tab. 2). This further clarifies the advantage of minimizing the phenomenon of rank reversal as proposed by the RAM method [31].

With all the results obtained from the analyses above, it's evident that when using the RAM method to rank options, the best approach is not dependent on the weights of the criteria. Adding 15% of the ATH reinforcement material to PVC is the optimal solution for manufacturing fire-resistant materials.

Weights of the criteria.

Normalized values in the RAM method.

Normalized values considering criteria weights.

Some parameters in RAM and the ranking of options.

|

Fig 1 Ranking of options. |

Spearman rank correlation coefficients.

5. Conclusion

The addition of ATH and ZB reinforcement materials to the base PVC enhances the fire resistance of the compounds. The optimization of the optimal solution regarding the type and amount of reinforcement material has been performed in this study. RAM and four methods for determining criteria weights were concurrently employed to achieve this objective. This research demonstrates that the use of RAM in combination with four different methods for determining weights has led to a stable result, with the same material option being consistently considered the best. Specifically, in all scenarios, the option containing 15% aluminum hydroxide reinforcement material (15ATH/PVC) was rated the highest. This showcases the consistency and stability of the RAM method in selecting the optimal solution in this case. This result also confirms the advantages of the RAM method as proposed, highlighting its capability to balance between favorable and unfavorable criteria and mitigate the occurrence of rank reversal.

In the future, several tasks need to be addressed, including: the selection of nanocomposite materials considering even more criteria; optimizing the production process of 15ATH/PVC nanocomposite materials to ensure the best performance and cost efficiency; conducting tests to ensure the stability and safety of 15ATH/PVC materials in fire-resistant environments and other practical applications; further exploration of different reinforcement materials to enhance the quality and fire resistance of PVC-based nanocomposite materials.

Funding

This research received no external funding.

Conflicts of interest

The author have nothing to disclose.

Data availability statement

Data sets generated during the current study are available from the corresponding author on reasonable request.

Author contribution statement

I am the sole author of the paper.

References

- R. Zivieri, On negative effective mass and negative group velocity in anharmonic seismic metamaterials, EPJ Appl. Metamat. 9, 10 (2022) [CrossRef] [EDP Sciences] [Google Scholar]

- S. Yang, K. Zhang, X. Ding, G. Yang, Q. Wu, Tailoring the scattering properties of coding metamaterials based on machine learning, EPJ Appl. Metamater. 8, 15 (2021) [CrossRef] [EDP Sciences] [Google Scholar]

- H. Bolat, P. Erkus, Use of polyvinyl chloride (PVC) powder and granules as aggregate replacement in concrete mixtures, Sci. Eng. Compos. Mater. 23, 209 (2016) [CrossRef] [Google Scholar]

- D.J. da Silva, G.B. Gramcianinov, P.Z. Jorge, V.B. Malaquias, A.A. Mori, M.H. Hirata, S.A.M. Lopes, L.A. Bueno, M. Champeau, D.J. Carastan, PVC containing silver nanoparticles with antimicrobial properties effective against SARS-CoV-2, Front. Chem. 11, 1083399 (2023) [CrossRef] [Google Scholar]

- N.M.K. Abdel-Gawad, A.Z. El Dein, D.-E.A. Mansour, H.M. Ahmed, M.M.F. Darwish, M. Lehtonen, Multiple enhancement of PVC cable insulation using functionalized SiO2 nanoparticles based nanocomposites, Electric Power Syst. Res. 163, 612 (2018) [CrossRef] [Google Scholar]

- K. Salasinska, K. Mizera, M. Celiński, P. Kozikowski, J. Mirowski, A. Gajek, Thermal properties and fire behavior of a flexible poly(vinyl chloride) modified with complex of 3-aminotriazole with zinc phosphate, Fire Safety Saf. J. 122, 103326 (2021) [Google Scholar]

- A.A. Basfar, 2002. Flame retardantcy of radiation cross-linked poly (vinyl chloride) (PVC) used as an insulating material for wire and cable, Polymer Degrad. Stabil. 77, 221 (2022) [CrossRef] [Google Scholar]

- P. Ye-Tang, T. Cédric, W. De-Yi, Hierarchical nanoporous silica doped with tin as novel multifunctional hybrid material to flexible poly (vinyl chloride) with greatly improved flame retardancy and mechanical properties, Chem. Eng. J. 295, 451 (2016) [CrossRef] [Google Scholar]

- G. Chai, G. Zhu, S. Gao, J. Zhou, Y. Gao, Y. Wang, On improving flame retardant and smoke suppression efficiency of epoxy resin doped with aluminum tri-hydroxide, Compos. Adv. Mater. 28, 1 (2019) [Google Scholar]

- A. Çetin, S. Gamze Erzengin, F. Burcu Alp, Various combinations of flame retardants for poly (vinyl chloride), Open Chem. 17, 980 (2019) [CrossRef] [Google Scholar]

- F. Alfawakhiri, C.J. Carter, Selecting the “right“ fire resistant design, Pract. Period. Struct. Des. Construct. 10, 3 (2005) [Google Scholar]

- Dao The Minh, Nghien cuu che tao vat lieu nanocompozit tren co so polyme nhiet deo (PE, PVC) va nano- clay de lam cap dien ben thoi tiet va kho chay., Science and technology topics (Vietnam Academy of Science and Technology, 2006) [Google Scholar]

- A.R. Horrocks, 6 – Nanocomposites II: potential applications for nanocomposite-based flame-retardant systems, in Advances in Fire Retardant Materials (Elsevier, 2008), pp. 124–158 [Google Scholar]

- S. Jayrajsinh, D. Gauri Shankar, Y.K. Agrawal, D. Lateef Bakre, Montmorillonite nanoclay as a multifaceted drug-delivery carrier: a review, J. Drug Deliv. Sci. Technol. 39, 200 (2017) [CrossRef] [Google Scholar]

- H. Pi, S. Guo, Y. Ning, Mechanochemical improvement of the flame-retardant and mechanical properties of zinc borate and zinc borate– aluminum trihydrate-filled poly(vinyl chloride), J. Appl. Polymer Sci. 89, 753 (2023) [Google Scholar]

- Y. Ning, S. Guo, Flame-retardant and smoke-suppressant properties of zinc borate and aluminum trihydrate-filled rigid PVC, J. Appl. Polymer Sci. 77, 3119 (2000) [CrossRef] [Google Scholar]

- Y. Li, L. Qi, Y. Liu, J. Qiao, M. Wang, X. Liu, S. Li, Recent advances in halogen-free flame retardants forpolyolefin cable sheath materials, Polymers 14, 1 (2022) [Google Scholar]

- W. Liu, Y. Jiang, N. Wang, W. Fu, Recent progress in flame retardant technology of battery: a review, Resources Chem. Mater. 2, 80 (2023) [Google Scholar]

- D.-S. Kim, B.-M. Lee, H.-R. Kim, S. Park, J.-S. Park, D. Hwang, J. Kim, J.-H. Choi, Preparation and characterization of poly(ethylene-co-vinyl acetate)/high-density polyethylene/aluminum hydroxide/clay composites by electron beam irradiation, Polymers Adv. Technol. 35, e6210 (2024) [Google Scholar]

- C. Kaynak, E. Ibibikcan, Contribution of nanoclays to the flame retardancy of polyethylene-based cable insulation materials with aluminum hydroxide and zinc borate, J. Fire Sci. 32, 121 (2013) [Google Scholar]

- A. Yücesoy, Y. Balçik Tamer, H. Berber, Improvement of flame retardancy and thermal stability of highly loaded low density polyethylene/magnesium hydroxide composites, J. Appl. Polymer Sci. 140, e54107 (2023) [Google Scholar]

- M.R. Petersen, A. Chen, M. Roll, S.J. Jung, M. Yossef, Mechanical properties of fire-retardant glass fiber-reinforced polymer materials with alumina tri-hydrate filler, Composites Part B: Eng. 78, 109 (2015) [CrossRef] [Google Scholar]

- E.R. Ghomi, F. Khosravi, Z. Mossayebi, A.S. Ardahaei, F.M. Dehaghi, M. Khorasani, R.E. Neisiany, O. Das, A.M. Rhoda Afriyie Mensah, L. Jiang, Q. Xu, M. Försth, F. Berto, S. Ramakrishna, The flame retardancy of polyethylene composites: from fundamental concepts to nanocomposites, Molecules 25, 5157 (2020) [CrossRef] [Google Scholar]

- L.D. Ha, Selection of suitable data normalization method to combine with the CRADIS method for making multi-criteria decision, Appl. Eng. Lett. 8, 24 (2023) [CrossRef] [Google Scholar]

- D.D. Trung, Application of EDAS, MARCOS, TOPSIS, MOORA and PIV methods for multi-criteria decision making in milling process, Strojnícky časopis, J. Mech. Eng. 71, 69 (2021) [Google Scholar]

- D.D. Trung, N. Nhu Tung, Applying COCOSO, MABAC, MAIRCA, EAMR, TOPSIS and weight determination methods for multi-criteria decision making in hole turning process, Strojnícky časopis, J. Mech. Eng. 72, 15 (2022) [Google Scholar]

- M. Baydas, Comparison of the performances of MCDM methods under uncertainty: an analysis on bist SME industry index, OPUS J. Soc. Res. 19, 308 (2021) [Google Scholar]

- M. Baydaş, T. Eren, Ž. Stević, V. Starčević, R. Parlakkay, Proposal for an objective binary benchmarking framework that validates each other for comparing MCDM methods through data analytics, PeerJ Computer Comput. Sci. 9, e1350 (2023) [CrossRef] [Google Scholar]

- A. Sotoudeh-Anvari, Root Assessment Method (RAM): a novel multi-criteria decision making method and its applications in sustainability challenges, J. Cleaner Prod. 423, 138695 (2023) [CrossRef] [Google Scholar]

- H.X. Thinh, Multi-objective optimization of turning process by FUCA method, Strojnícky časopis, J. Mech. Eng. 73, 55 (2022) [Google Scholar]

- D.D. Trung, H.X. Thinh, A multi-criteria decision-making in turning process using the MAIRCA, EAMR, MARCOS and TOPSIS methods: a comparative study, Adv. Prod. Eng. Manage. 16, 443 (2021) [Google Scholar]

- F. Ecer, D. Pamucar, A novel LOPCOW-DOBI multi-criteria sustainability performance assessment methodology: an application in developing country banking sector, Omega 112, 102690 (2022) [CrossRef] [Google Scholar]

- T.C. Doanh, V.M. Tan, H.T. Oanh, H.T. Nhung, H.M. Ha, Preparation and charaterization of flame retardant nanocomposite based on polyvinyl chloride, J. Sci. Technol. 57, 115 (2021) [Google Scholar]

- D. Bozanic, A. Milic, D. Tesic, W. Sałabun, D. Pamucar, D numbers – fucom – fuzzy rafsi model for selecting the group of construction machines for enabling mobility, FACTA Universitatis, Mech. Eng. 19, 447 (2021) [Google Scholar]

- L.J. Muhammad, I. Badi, A.A. Haruna, I.A. Mohammed, Selecting the best municipal solid waste management techniques in nigeria using multi criteria decision making techniques, Rep. Mech. Eng. 2, 180 (2021) [CrossRef] [Google Scholar]

- M. Radovanović, A. Petrovski, A. Behlić, M. Perišić, M. Samopjan, B. Lakanović, Application model of MCDM for selection of automatic rifle, J. Decis. Analyt. Intell. Comput. 3, 185 (2023) [CrossRef] [Google Scholar]

Cite this article as: Do Duc Trung, Using RAM method for optimal selection of flame retardant nanocomposite material fabrication solution. EPJ Appl. Metamat. 11, 4 (2024)

All Tables

All Figures

|

Fig 1 Ranking of options. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.